Chemistry, Manufacturing, and Controls (CMC) clinical trials represent a critical component of the drug development process, focusing on the quality and consistency of pharmaceutical products. CMC encompasses the scientific and regulatory aspects that ensure a drug’s active ingredients, formulation, and manufacturing processes meet stringent standards. These trials are essential for demonstrating that a drug can be produced reliably and safely, which is a prerequisite for regulatory approval.

The significance of CMC clinical trials extends beyond mere compliance; they are integral to ensuring that patients receive medications that are not only effective but also safe and of high quality. The CMC process begins long before a drug reaches the clinical trial phase. It involves extensive research and development to establish the drug’s formulation, stability, and manufacturing processes.

This groundwork is crucial because any variability in these factors can lead to significant differences in drug efficacy and safety. As such, CMC clinical trials serve as a bridge between laboratory research and clinical application, ensuring that the transition from bench to bedside is both smooth and scientifically sound. The rigorous nature of these trials reflects the pharmaceutical industry’s commitment to patient safety and therapeutic effectiveness.

Key Takeaways

- CMC clinical trials are essential for ensuring the quality, safety, and efficacy of pharmaceutical products.

- They play a critical role in advancing medicine by supporting drug development and regulatory approval.

- The process involves rigorous testing of chemistry, manufacturing, and controls to maintain product consistency.

- CMC trials directly impact patient care by ensuring reliable and effective treatments reach the market.

- Ongoing challenges include ethical considerations and adapting to future innovations in trial methodologies.

The Importance of CMC Clinical Trials in Advancing Medicine

CMC clinical trials play a pivotal role in advancing medicine by ensuring that new therapies are developed with a focus on quality and reliability. The pharmaceutical landscape is increasingly complex, with the introduction of biologics, biosimilars, and advanced therapies such as gene editing and cell therapy. Each of these innovations requires a robust CMC framework to address unique challenges related to their production and quality assurance.

For instance, biologics often involve living organisms in their production, necessitating stringent controls to prevent contamination and ensure consistent potency. Moreover, the importance of CMC clinical trials is underscored by the growing emphasis on personalized medicine. As treatments become more tailored to individual patient profiles, the need for precise manufacturing processes becomes even more critical.

CMC trials help establish the necessary parameters for producing these customized therapies, ensuring that they meet the specific needs of diverse patient populations. This focus on quality not only enhances patient outcomes but also fosters trust in the healthcare system, as patients can be assured that the medications they receive are both safe and effective.

The Role of CMC Clinical Trials in Drug Development

In the drug development continuum, CMC clinical trials serve as a foundational pillar that supports the entire process from discovery through to commercialization. These trials are designed to evaluate various aspects of drug production, including formulation development, stability testing, and manufacturing scalability. By addressing these elements early in the development process, pharmaceutical companies can identify potential issues that may arise during later stages, thereby mitigating risks associated with regulatory approval.

For example, during the formulation development phase, CMC trials assess how different excipients interact with the active pharmaceutical ingredient (API). This interaction can significantly influence the drug’s bioavailability and overall therapeutic effect. By conducting thorough CMC trials at this stage, developers can optimize formulations to enhance patient outcomes.

Additionally, scalability studies conducted during CMC trials ensure that manufacturing processes can be effectively scaled up from laboratory settings to commercial production without compromising quality or efficacy.

The Process of Conducting CMC Clinical Trials

Conducting CMC clinical trials involves a systematic approach that encompasses several key stages. Initially, researchers must define the objectives of the trial, which typically include evaluating the drug’s formulation, assessing its stability under various conditions, and determining the manufacturing process’s robustness. This stage often involves collaboration between chemists, biologists, and regulatory experts to ensure that all aspects of the drug’s development are considered.

Once objectives are established, researchers proceed with formulation development and stability testing. This phase may involve creating multiple formulations to identify the most effective combination of ingredients. Stability studies are crucial at this stage; they assess how environmental factors such as temperature, humidity, and light exposure affect the drug over time.

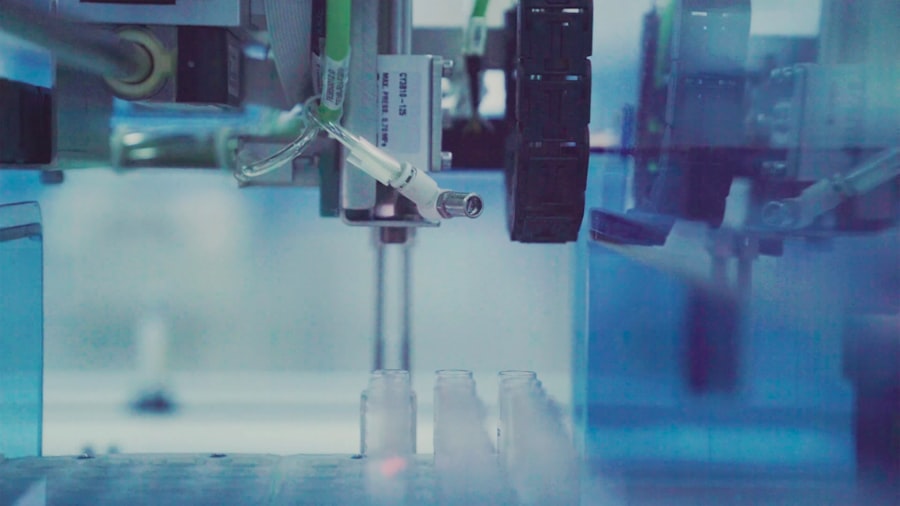

These studies help determine appropriate storage conditions and shelf life, which are vital for ensuring patient safety. Following formulation and stability testing, the focus shifts to manufacturing processes. This includes developing protocols for large-scale production while maintaining quality control measures.

CMC clinical trials often involve pilot batches to evaluate how well the manufacturing process translates from small-scale to large-scale production. Throughout this process, data is meticulously collected and analyzed to ensure compliance with regulatory standards set forth by agencies such as the U.S. Food and Drug Administration (FDA) or the European Medicines Agency (EMA).

The Impact of CMC Clinical Trials on Patient Care

| Metric | Description | Typical Range/Value | Importance in CMC Clinical Trials |

|---|---|---|---|

| Batch Size | Quantity of drug substance produced per batch | 1 kg to 100 kg | Ensures consistency and scalability of manufacturing process |

| Purity (%) | Percentage of active pharmaceutical ingredient (API) free from impurities | ≥ 98% | Critical for safety and efficacy of the drug product |

| Stability Duration | Time period the drug product remains within specifications | 12 to 36 months | Determines shelf life and storage conditions |

| Impurity Levels | Amount of unwanted substances in the drug substance | < 0.5% | Regulatory requirement to minimize patient risk |

| Potency | Measure of drug activity expressed in units or concentration | 95% to 105% of label claim | Ensures therapeutic effectiveness |

| Microbial Limits | Acceptable levels of microbial contamination | Less than 100 CFU/g for non-sterile products | Ensures product safety and compliance |

| Endotoxin Levels | Amount of bacterial endotoxins present | < 0.5 EU/mL | Critical for injectable products to prevent pyrogenic reactions |

| Release Testing Time | Time taken to complete quality control tests before batch release | 3 to 7 days | Impacts clinical trial timelines and drug availability |

The impact of CMC clinical trials on patient care is profound and multifaceted. By ensuring that drugs are manufactured consistently and meet high-quality standards, these trials directly contribute to patient safety and treatment efficacy. For instance, when a new cancer therapy undergoes rigorous CMC testing, it is more likely to deliver consistent therapeutic outcomes across diverse patient populations.

This consistency is crucial in oncology, where variations in drug potency can significantly affect treatment success. Furthermore, CMC clinical trials facilitate faster access to new therapies by streamlining the regulatory approval process. When pharmaceutical companies can demonstrate robust manufacturing processes through comprehensive CMC data, regulatory agencies are more likely to expedite reviews and approvals.

This acceleration is particularly important in urgent medical situations, such as during public health emergencies or when addressing unmet medical needs in chronic diseases.

Challenges and Opportunities in CMC Clinical Trials

Despite their critical importance, CMC clinical trials face several challenges that can hinder progress in drug development. One significant challenge is the complexity of modern therapeutics, particularly biologics and gene therapies. These products often require sophisticated manufacturing techniques that can be difficult to standardize across different production facilities.

Variability in raw materials or changes in manufacturing conditions can lead to inconsistencies in product quality, posing risks to patient safety. Additionally, regulatory requirements for CMC data can be stringent and evolving. As regulatory agencies adapt to new scientific advancements and technologies, pharmaceutical companies must remain agile in their approach to compliance.

This dynamic environment presents both challenges and opportunities; companies that invest in innovative manufacturing technologies or adopt advanced analytics for quality control may gain a competitive edge in bringing new therapies to market.

Ethical Considerations in CMC Clinical Trials

Ethical considerations are paramount in CMC clinical trials, particularly regarding patient safety and informed consent. Ensuring that drugs are manufactured according to high-quality standards is not just a regulatory requirement; it is an ethical obligation to protect patients who will ultimately use these therapies. Any lapses in quality control can have dire consequences for patient health, making it essential for pharmaceutical companies to prioritize ethical practices throughout the CMC process.

Moreover, transparency in reporting CMC trial results is crucial for maintaining public trust in the pharmaceutical industry. Stakeholders—including patients, healthcare providers, and regulatory agencies—must have access to clear information about how drugs are manufactured and tested. This transparency fosters accountability and encourages ethical behavior within the industry.

Future Directions in CMC Clinical Trials

Looking ahead, the future of CMC clinical trials is poised for transformation driven by technological advancements and evolving regulatory landscapes. One promising direction is the integration of artificial intelligence (AI) and machine learning into CMC processes. These technologies can enhance data analysis capabilities, allowing for more efficient identification of potential quality issues during manufacturing.

By leveraging AI algorithms to predict outcomes based on historical data, companies can optimize their processes proactively rather than reactively. Additionally, as personalized medicine continues to gain traction, CMC clinical trials will need to adapt to accommodate smaller batch sizes tailored for individual patients or specific populations. This shift will require innovative manufacturing solutions that maintain quality while allowing for flexibility in production scales.

The rise of continuous manufacturing techniques may also play a significant role in this evolution by enabling real-time monitoring of product quality throughout the production process. In conclusion, as we move forward into an era characterized by rapid scientific advancements and increasing patient expectations, CMC clinical trials will remain a cornerstone of drug development. Their role in ensuring quality and safety will be more critical than ever as we strive to deliver effective therapies that meet diverse patient needs across various therapeutic areas.